Equipment, Environment, and Teams: Monitoring Solutions for the Mid-Sized Laboratory

As a laboratory grows and evolves from a start-up to medium-sized to (perhaps eventually) what we’ll call large or enterprise-sized, its needs evolve as well: equipment, people, environmental stability, security, and compliance.

Note that the growth of a laboratory is not necessarily in square footage. It’s typically in levels of sophistication, as they move from a single scientist working off the bench… toward a small team… toward commercial viability… and then toward fully operational, with compliance, sales, and other teams taking products to market… and then, maybe, toward being a household name (Bayer, Pfizer, J&J, etc.).

The middle stage — as a laboratory moves from start-up to medium-sized, with commercialization in its sights — is perhaps the trickiest one. It’s in this stage where new processes, workflows, and equipment may be introduced, new players and team members are getting involved, and both the rewards - and the risks - become more evident…

Learn more about monitoring services for Biotechnology and Pharmaceutical companies on our industry page.

Simply put, the stakes are higher for a medium-sized laboratory than for a start-up or enterprise, This makes monitoring every resource, workspace, and workflow critical. Following, we’ll dig into three specific components: equipment, environment, and teams.

Monitoring Lab Equipment and its Critical Conditions

The more sophisticated a lab becomes, the more sophisticated equipment it often requires. And sophisticated equipment usually requires careful, consistent, and constant oversight.

For example, during the start-up phase, a laboratory may only be concerned with basic equipment metrics, like temperature and up-time. But more complex equipment may require monitoring of several other factors, such as humidity, CO2, O2, pH, shaking/stability, and more.

As a lab grows, more pieces of equipment are added, and more people are hired to use and maintain it. With more people interacting, more variables are introduced that require careful monitoring to ensure the work stays pure and on track.

More employees in the lab doing tasks means more foot traffic which makes it harder to get around. Or more people are using a fridge, so by the time you return the sample, your space is gone, and you need to find a new freezer.

Additionally, more equipment and square footage mean more data to be collected and analyzed. In the start-up world, the principal researcher can typically easily assess — even simply by “eyeballing” — what’s happening with the equipment in their facility. However, data collection can quickly become a full-time job in a medium-sized laboratory with more players and pieces.

The good news is that it’s a job that can mostly be automated using sensors and gauges that capture data and feed it to an overarching monitoring system, enabling any lab manager to have immediate and actionable insight on every piece of equipment — no matter how many are in operation.

Environmental Monitoring in the Laboratory

A shift in temperature, humidity, or air quality can derail most lab work, and force a growing lab back on its heels as it tries to recover. Monitoring critical environmental factors is necessary to ensure a lab’s work — and growth — stays on track.

To take one specific example: freezers. Yes, freezers are equipment and must be monitored as such (door openings, internal temperature stability, predictive maintenance). This is easy enough when you have only one, and having only one is highly unlikely to impact the overall environment within a laboratory.

But when you have more than one (as a growing laboratory often does), more factors are introduced (impact on the power supply and HVAC systems), and dependencies are created that make this an environmental variable.

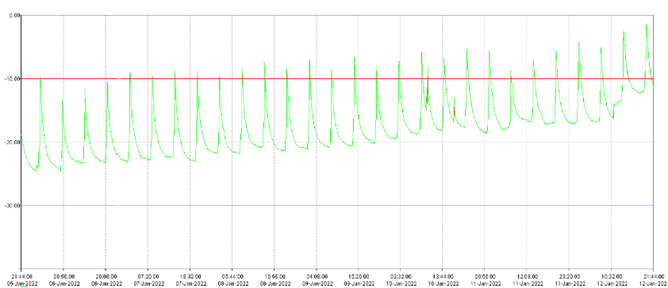

The following graph indicates the rise in temperature in a freezer as a growing laboratory adds more freezers to the existing space. With a real-time data acquisition system, you can locate the exact time when the temperature started to rise and determine the root cause of this rise was due to the HVAC system not being able to cool enough due to heat expelled from the additional freezers.

This real-time data shows the environmental impact when a growing lab adds equipment but has not yet added space. And this kind of data would not be available through a traditional data logging system. Only through a continuous monitoring system can you collect, analyze, and act on this comprehensive data set and ensure the integrity of your environment. (Learn more about real-time monitoring vs. data logging.)

There’s a myriad of factors that can impact the air quality in a lab: VOCs (volatile organic compounds) that may leak in through an HVAC system, external weather events, power outages… the list is virtually endless. (Fortunately, for start-up, medium-size, and enterprise-level laboratories, there’s a book on the subject.)

Teams: Where it All Comes Together… or All Falls Apart

A great thinker once said, “The problem is what it always is: people.” We say the SOLUTION is people.

The people attached to the processes are a cornerstone of success in the lab. Especially when it comes to ensuring the efficacy of your equipment, the proper execution of workflows, and the purity of your environment.

But people are flawed… they may unknowingly bring VOCs into the space, wear a fragrance that impacts a study, or accidentally leave a freezer door open. So as your laboratory and its team grow, your methodologies must change to accommodate this growth.

Introduce SOPs around equipment and facilities. Train staff in understanding not only how the equipment works, but how it’s monitored and how that monitoring data is used to prevent disaster and increase research reproducibility.

Introduce SOPs around equipment and facilities. Train staff in understanding not only how the equipment works, but how it’s monitored and how that monitoring data is used to prevent disaster and increase research reproducibility.

Embrace the new and changing needs of staff as work progresses, and ensure how you’re monitoring your equipment and facilities accommodates those needs. (E.g., a team wants to work the weekend? Ensure your freezer parameters are set for a weekday environment, to widen limits and avoid false alarms from frequent door openings)

Also, when you add people to your practice, you add complexity to workflows, compliance, and more. With a scalable monitoring system in place, managing complexities is nearly automated, and in the event of, for example, an audit, demonstrating compliance is simplified through built-in reporting tools.

Your team can - and should - extend beyond your four walls, too, with a team dedicated to monitoring your facility, environment, and equipment. This is where XiltriX can help with monitoring-as-a-service.

No need to invest in teams to manage monitoring and reporting: it’s provided as a service. No need to invest in the hardware, sensors, and more as it’s provided as a service.

The last thing a lab needs as it moves from start-up to mid-sized to enterprise is to be slowed down by improperly overseen facilities and equipment, which is why it needs a system that is flexible and scalable.

XiltriX ensures the equipment, environment, and people tied to your work are running cleanly and completely. Learn about equipping your lab with a custom monitoring service that will scale with you. Contact us now: