Particle counting is a key feature of air quality monitoring in laboratories across a range of science and technology disciplines, including biotechnology, biopharmaceuticals production, semiconductor development and manufacture, nanotechnology labs--and in fact any laboratory where there are products or processes that are in any way sensitive to environmental contamination.

Particle counting is a key feature of air quality monitoring in laboratories across a range of science and technology disciplines, including biotechnology, biopharmaceuticals production, semiconductor development and manufacture, nanotechnology labs--and in fact any laboratory where there are products or processes that are in any way sensitive to environmental contamination.

Particle Counting in a Laboratory

It is essential in the manufacturing of pharmaceuticals, superconductors, and many other high-quality products to maintain a fastidious degree of sterility and air purity at all times, in order to ensure that all finished products are contaminant-free and that they meet the relevant regulatory standards. The use of particle counting instruments, which are also often used for particle sizing, is therefore necessary to monitor air quality parameters in the modern laboratory setting.

Types of Particle Counters

There are a variety of particle counters available. In many of these instruments, particles are counted as they pass through a detection chamber, where they are illuminated by a high intensity light source. The total number of particles present in an air sample can then be detected using one of a few different approaches.

Light Scattering Particle Counting

In the process known as light-scattering particle counting, light is deflected by particles in the detection chamber sample, and that deflected light is then measured using a photo-sensor.

Light Obscuration

In light obscuration, or light-blocking devices, the photo-sensor detects any reductions in light arising from the presence of particulate matter in the sample being analyzed.

Imaging Particle Counting

Also known as direct imaging particle counting. Involving the use of sophisticated computer imaging software, a video is recorded in high definition and analyzes the amount of particles in a sample illuminated via a high-intensity beam of light.

Particle counting instruments come in different sizes, and may be used for slightly different functions in a laboratory setting. Small, portable, handheld particle counters are useful for taking measurements in many different locations for regular checks on air quality throughout a lab. Larger particle counters may be fixed in one place, and these are then used to analyze greater volumes of air. They may be run on a 24/7 basis for long-term monitoring of air quality.

Biotechnology and biopharmaceutical labs in particular are concerned with maintaining a clean atmosphere to ensure the integrity and purity of their final products. In these kinds of working environments, it is important to monitor the aerosol particle concentration – that is, the number of particles in the air. An airborne particle counter is an essential measuring instrument used to detect particles in the air and quantify them. Aerosol particle counters can be used to determine the amount and size of particulate matter in the atmosphere.

Some highly specialized labs handling ultra-sensitive materials may need an even more specialized particle counting instrument, known as a condensation particle counter. Conventional optical particle counters generally can't detect or measure particles that are smaller than 50 nm in size.

Condensation particle counters, however, can detect particles that are less than 50 nm. They can detect particles down to an incredibly small 2 nm in size. They are able to do this because they first use particles from the area being tested as nucleation centers to create droplets in a supersaturated gas. This process is similar to the way that nucleation centers in the atmosphere form clouds through the process of condensation, but on a significantly smaller scale – hence the name of these instruments.

Particulate matter that is detectable in the air can be classified into two types: viable and non-viable particles. Viable particles refer to living microorganisms present in the air, and include bacteria, fungi, and fungal spores. The size distribution of viable particles may range from 0.2 to 30 micrometers. In order to count viable particles, they must first be collected in such a way so as to not kill the microorganisms. Next, the particles are inoculated on an appropriate culture medium, to grow them up so that they can be counted.

Non-viable particles are non-living particles, but they may transport living particles on them. The general size of non-viable particles that are monitored ranges from between 0.5 to 5 micrometers.

Meeting and Maintaining Air Quality Standards

Many types of modern laboratory operations must often take measures to ensure that air quality is maintained to the highest of standards. These standards become even more stringent when cleanrooms are required, such as in the manufacture of semiconductors, disk drives, or aerospace components, or in the development and production of pharmaceuticals and biotech products, such as vaccines or monoclonal antibodies.

In high-tech industries like these, components, ingredients, instruments, or products may be highly sensitive to even the slightest hint of contamination. Cleanroom air quality standards are thus highly demanding, and require innovative solutions to monitor and detect particulates in the air, and to report any deviations from standards if they occur in a timely fashion.

Air quality parameters in biotech, biopharmaceutical, and many other modern laboratory environments must therefore be continuously monitored and assessed. One way to help you observe and control the optimum conditions in your lab, and to maintain a consistent environment that meets all regulatory and product specification guidelines, is to use an automated, computerized laboratory monitoring and control system, such as XiltriX.

XiltriX includes particle counting as part of its monitoring processes. The system can be set up to monitor remote particle counters, and will send alarm notifications to relevant staff if particle number or size, or other air quality parameters, deviate from the specified standards.

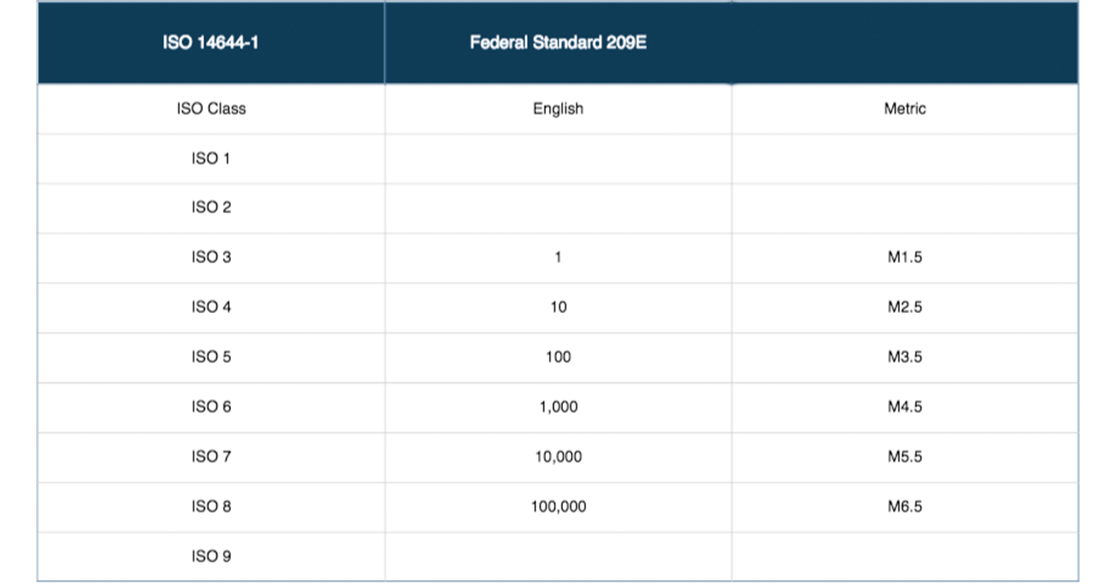

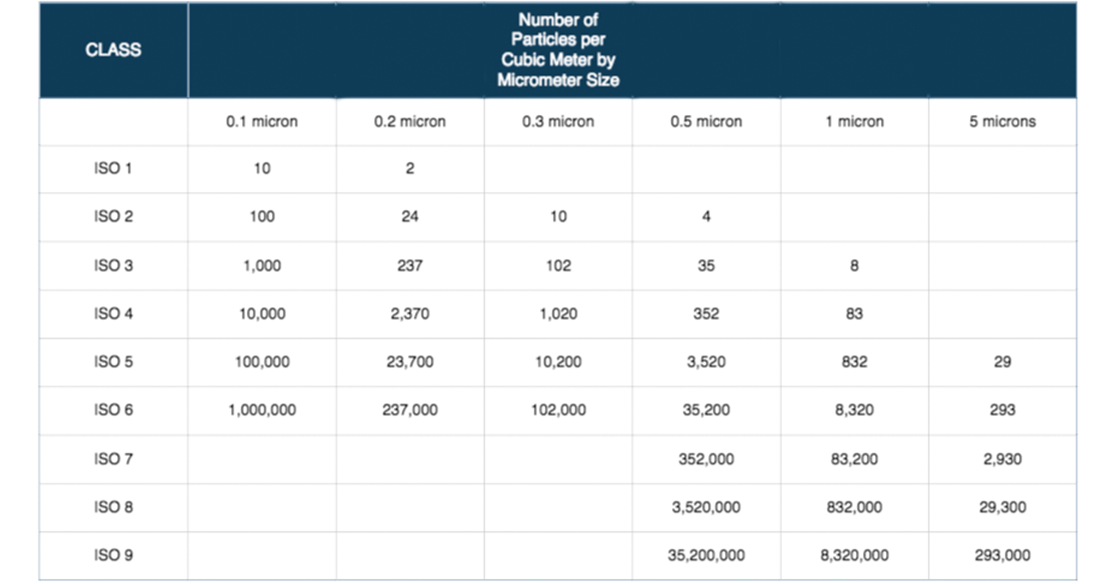

It also records all of the air quality and particle counting results, which can subsequently be used to provide evidence during quality control audits, validation exercises, and any other reporting requirements. Cleanrooms in particular have strictly defined limits as to what level of particulate matter is acceptable in them, in order to meet mandated quality standards. These standards contain 9 classes, each of which must adhere to different testing and parameters.

See the charts below for a break-down of each classification:

Airborne Particulate Cleanliness Class Comparison:

Airborne Particulate Cleanliness Classes (by cubic meter):

A monitoring system such as XiltriX, which provides warning alarms in real-time should there be any problem with particulate levels, is therefore an indispensable feature of the modern laboratory.

To learn more about how different factors affect laboratory air quality, download our white paper "Air Quality in the Lab":