Life science facilities are not strangers to the notoriously difficult task of keeping samples and equipment free from humidity damage. Despite the persistent need to also monitor and control the relative humidity (RH) of these spaces, many facilities put themselves through a frustrating maintenance process involving HVAC systems and dehumidifiers.

Why Real-time Monitoring of Temperature & Humidity is Crucial for Laboratories

Life science facilities are not strangers to the notoriously difficult task of keeping samples and equipment free from humidity damage. A sizable amount of laboratory work requires temperature-controlled spaces, ranging from small vivariums to bulk incubators to entire warehouses. Despite the persistent need to also monitor and control the humidity of these spaces, many facilities put themselves through a frustrating maintenance process involving HVAC systems and dehumidifiers. One organization, in its search for an advanced data acquisition system, noted that there were several cold spots in an incubator that would create condensation. While this typically happens when H2O is present in the incubator, this condensation actually consisted of oil droplets that had evaporated off of the samples themselves. With oil now dripping down the incubator and mold forming in its crevices, the incubator began to malfunction, compromising all of the samples and costing the organization thousands of dollars.

The World Health Organization has weighed in on the subject, given the persistence of the problem, and asserts that “temperature, relative humidity, and ventilation should be appropriate and should not adversely affect the quality of pharmaceutical products during their manufacture and storage, or the accurate functioning of equipment.” Fortunately for organizations such as this one, real-time monitoring systems allow them to take a proactive approach to humidity control, rather than a reactive approach once damages have already occurred.

Protecting Assets by Monitoring Temperature and Humidity in Real-Time

Close monitoring of both temperature and humidity is the key to keeping life science environments free from substantial losses. Relative humidity (Rh) is the ratio of the actual water vapor pressure of the air to the saturated water vapor pressure of the air at the same temperature expressed as a percentage. More simply put, it is the ratio of the mass of moisture in the air, relative to the mass at 100% moisture saturation, at a given temperature. Moisture in the atmosphere plays a threatening role in the deterioration of samples that are either stored incorrectly or in transit. Even cardboard boxes can become damaged if not in well-monitored conditions.

High-quality humidity sensors and temperature sensors must be professionally installed in facilities that are concerned with controlling humidity. Furthermore, lab employees must be able to integrate the data from different sensors and have access to 24/7 insight into it because of how discreetly deviations can occur. Since weather conditions outside of the lab are constantly changing - whether daytime to nighttime or winter to spring - it is essential that facilities monitor conditions continuously rather than relying on an initial validation or mapping. Metadata such as this - the temperature in the room in relation to the incubator - is often overlooked though it holds the key to regulating changes in temperature and consequential humidity. Facilities that are keen on the sensitive nature of temperature and humidity consistently adjust inside conditions to keep all samples safe and dry, paying attention to the comprehensive overlay of data coming from their sensors. Otherwise, organizations will suffer from compromised data and even harmful atmospheric pollutants.

Benefits of Monitoring Temperature and Humidity

-> Saving Money

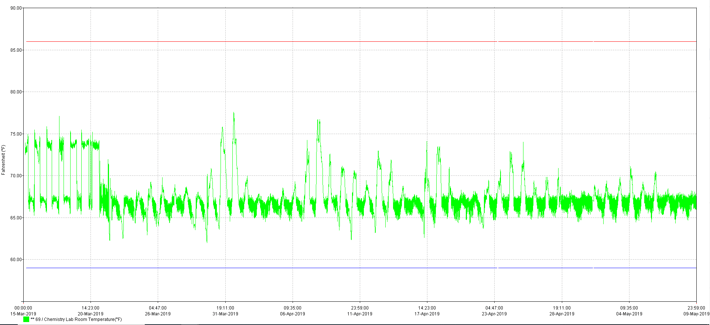

HVAC system regulation can prevent unnecessary energy expenses that occur when it is overworked. In the image below, the HVAC system was fighting with fume hoods in the lab and causing huge temperature changes. Independent, calibrated sensors were implemented in the room, and data gathered was used to optimize HVAC cycles and save on energy consumption.

-> Reduced Risk

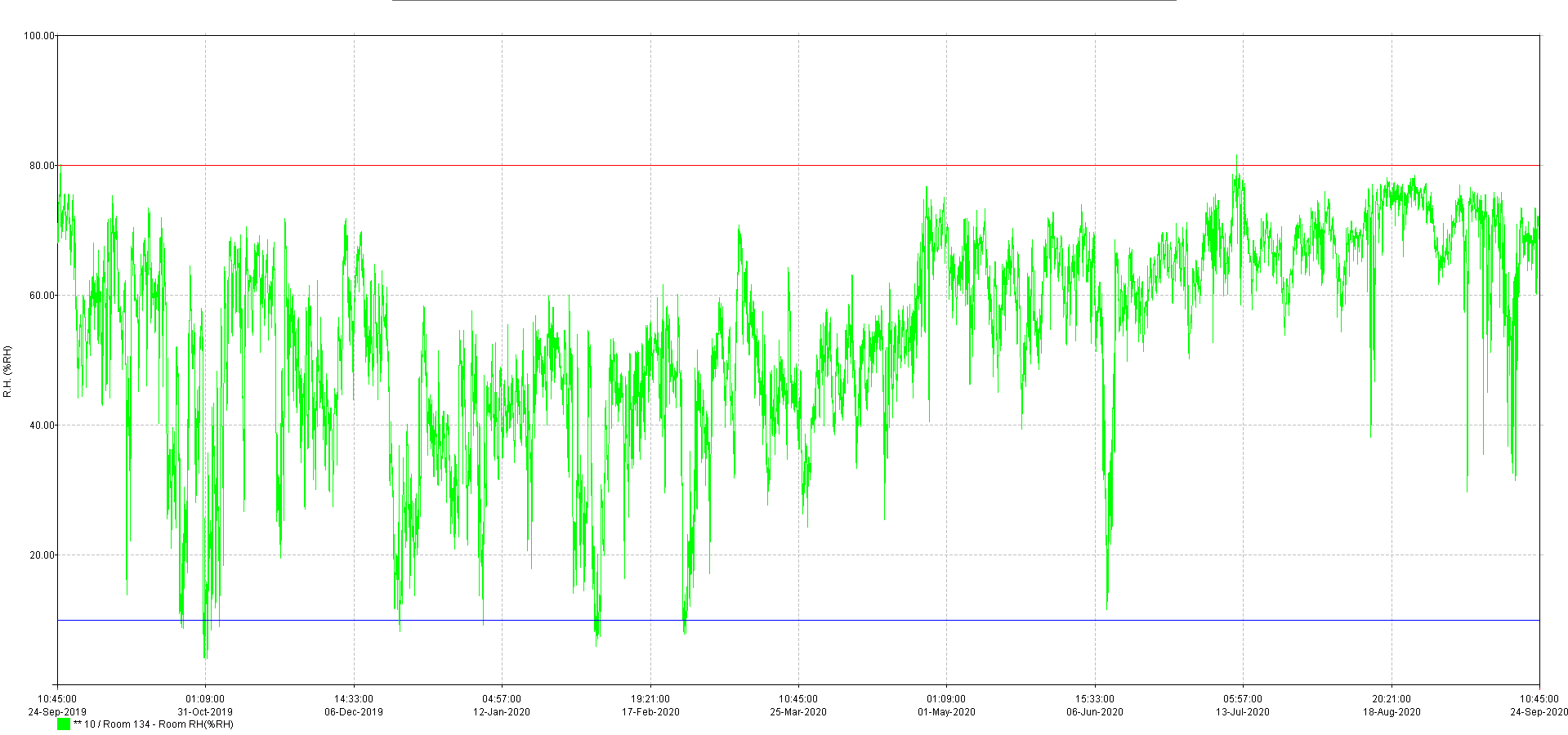

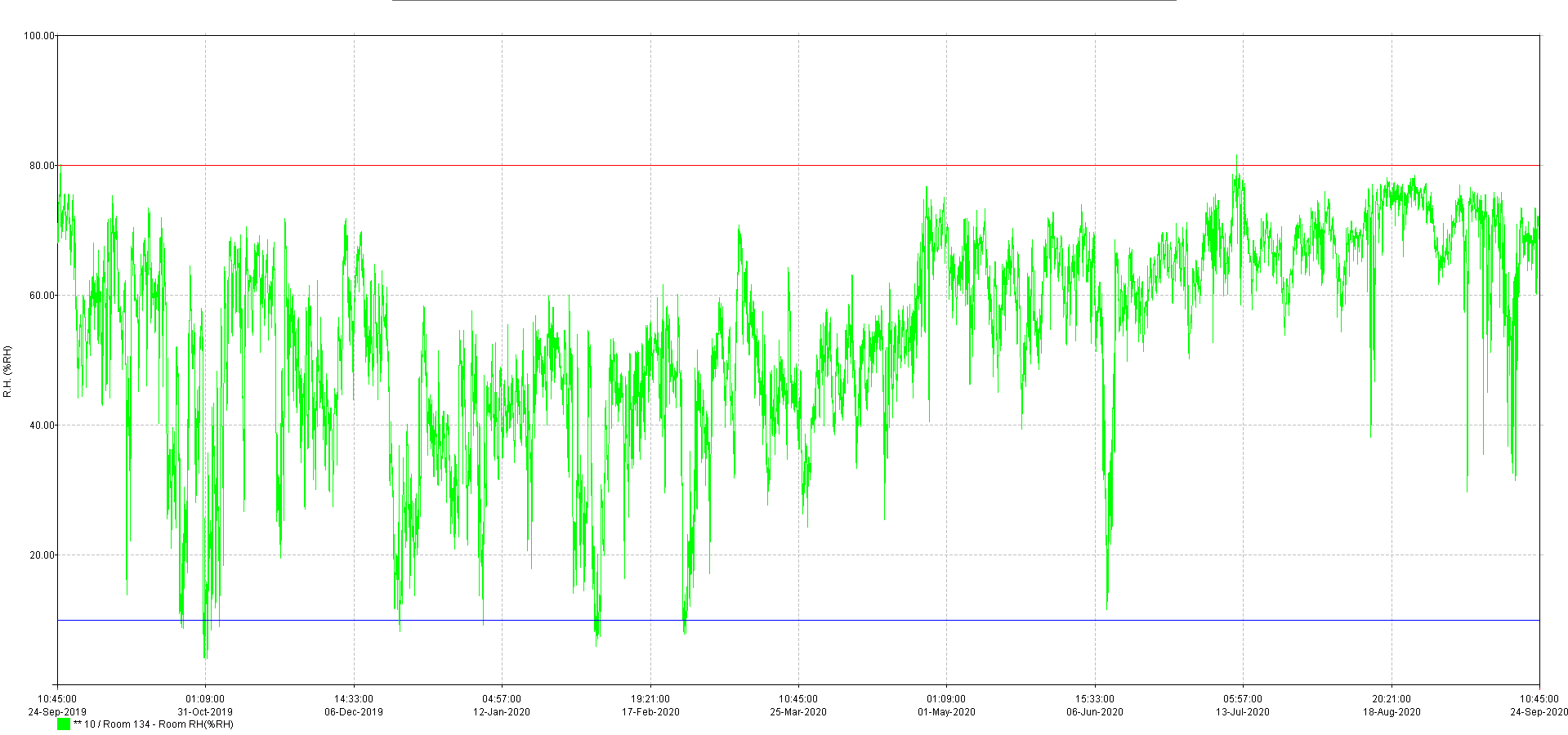

The data set below highlights the varying humidity levels throughout the year in a highly controlled hospital environment. Understanding fluctuations - and implementing processes to control them - minimizes humidity’s adverse effects on critical equipment and specialty pharmaceuticals. With increased control over the facility, this hospital can reduce potential risks of complications for their patients and minimize the deterioration of expensive equipment.

-> Increase Research Reproducibility

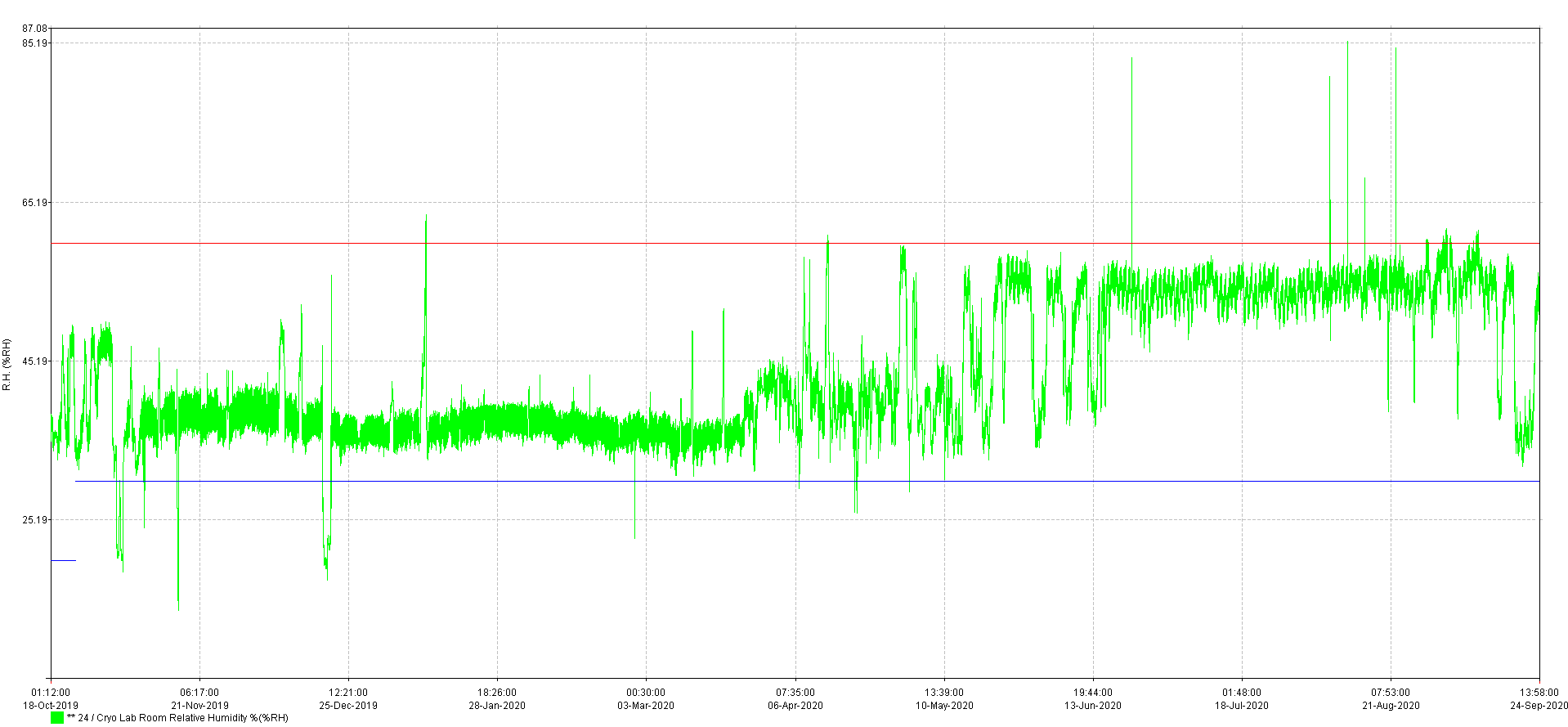

Identifying data points and thresholds early on in the research and development phases can help guide Environmental Monitoring programs and alarm limits in the scale-up and production phase. The data below comes from an R&D facility for pharmaceuticals that used historical data to shape environmental monitoring protocols when scaling from development to commercialization.

-> Objective, Third-Party Data

Each graph displayed above is the work of a real-time, data acquisition system that allows these users to improve the quality of their science across the board. These systems keep organizations in tune with the nuances behind developing and producing quality scientific assets, further enabling them to increase profit and productivity. The interaction between relative humidity and temperature is one strong example of why these nuances must be monitored carefully.

Looking to reduce the burden of error-filled, manual recording? XiltriX North America leverages industrial-grade hardware, a user-friendly cloud-based software platform, and 30 years of experience in life science environments to provide a high-value-added service to organizations of any size. We provide a sensor-agnostic solution to monitor temperature and humidity within your facility. Integrating outputs from both equipment and environmental conditions in real-time and leveraging state-of-the-art sensors, XiltriX provides a holistic view of your facility, proactively addressing issues before they become catastrophes.

Request a demo today and learn how XiltriX can provide you with complete peace of mind.